Intense Pulsed Ion Beams

Blake P. Wood (P-24), bwood@lanl.gov,

(505)665-6524

For more photos of the CHAMP system, click here.

The material in this web page is excerpted from LAUR-99-991.

Background and Research Objectives

Intense Pulsed Ion Beams (IPIB) have been under investigation for a number of years in

Japan, the Former Soviet Union, Germany, and the United States for materials processing

applications [1-7]. Such IPIB devices typically produce beams of 10's of kiloamps current

at 100's to 1000's of kilovolts, in pulses of 50 -1000 ns. Although these are called

"ion beams", they are, in fact beams of neutral plasma - although only the ions

are initially accelerated, electrons are pulled off surfaces to provide quasi-neutrality.

For approximately

eight years, LANL has operated the Anaconda IPIB [9]. Anaconda utilizes the ballistically

focused, magnetically insulated ion diode shown at left, a common anode design. Ions are

formed by the flashover of a conical annulus of Lucite attached to the anode electrode.

Ions are accelerated across a 300 kV gap toward nested, truncated metal cones that form

the cathode. Field-emitted cathode electrons are prevented from shorting the anode-cathode

gap by a transverse magnetic field generated by pulsed electromagnets ("slow

coils") which surround the cathode cone. The azimuthal E(B drift of electrons in the

anode-cathode gap causes them to stay confined. The diode is directly connected to a Marx

generator operated to produce a 300 keV, 30 kA, 400 ns beam. The ballistic focus of the

diode produces a minimum spot size of about 100 cm2, yielding energy fluences

at focus of about 30 J/cm2.

For approximately

eight years, LANL has operated the Anaconda IPIB [9]. Anaconda utilizes the ballistically

focused, magnetically insulated ion diode shown at left, a common anode design. Ions are

formed by the flashover of a conical annulus of Lucite attached to the anode electrode.

Ions are accelerated across a 300 kV gap toward nested, truncated metal cones that form

the cathode. Field-emitted cathode electrons are prevented from shorting the anode-cathode

gap by a transverse magnetic field generated by pulsed electromagnets ("slow

coils") which surround the cathode cone. The azimuthal E(B drift of electrons in the

anode-cathode gap causes them to stay confined. The diode is directly connected to a Marx

generator operated to produce a 300 keV, 30 kA, 400 ns beam. The ballistic focus of the

diode produces a minimum spot size of about 100 cm2, yielding energy fluences

at focus of about 30 J/cm2.

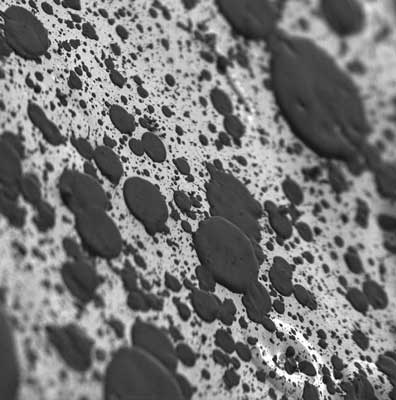

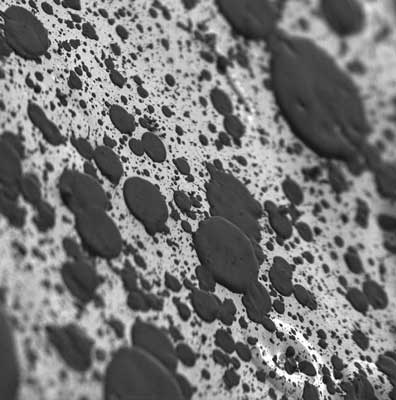

There are several

limitations of this solid flashover ion diode design. The beam produced consists of

carbon, hydrogen, and oxygen ions, with little composition control possible. Anode debris

(molten bits of anode material) is produced, which impacts and contaminates the object

being treated. Such debris is shown at left. Finally, due to the large amount of vapor and

anode debris produced, it requires a significant amount of time (seconds to minutes) to

pump the vacuum chamber down in preparation for the next shot.

There are several

limitations of this solid flashover ion diode design. The beam produced consists of

carbon, hydrogen, and oxygen ions, with little composition control possible. Anode debris

(molten bits of anode material) is produced, which impacts and contaminates the object

being treated. Such debris is shown at left. Finally, due to the large amount of vapor and

anode debris produced, it requires a significant amount of time (seconds to minutes) to

pump the vacuum chamber down in preparation for the next shot.

A better anode design is the active anode plasma diode developed

by John Greenly at Cornell University.[10, 11]. This diode looks very much like the

Anaconda diode shown above, but replaces the solid flashover anode with a plasma produced

by breaking down gas which has been puffed across the face of the anode from a fast valve

on the diode axis. The anode face consists of a "fast" inductive coil potted in

epoxy. Pulsing the fast coil breaks down the gas into a plasma. This plasma is stagnated

against the transverse magnetic field produced by the slow coils, and ions are

subsequently extracted by the high voltage accelerating pulse. The active anode plasma

diode designed and constructed for CHAMP is shown at left.

A better anode design is the active anode plasma diode developed

by John Greenly at Cornell University.[10, 11]. This diode looks very much like the

Anaconda diode shown above, but replaces the solid flashover anode with a plasma produced

by breaking down gas which has been puffed across the face of the anode from a fast valve

on the diode axis. The anode face consists of a "fast" inductive coil potted in

epoxy. Pulsing the fast coil breaks down the gas into a plasma. This plasma is stagnated

against the transverse magnetic field produced by the slow coils, and ions are

subsequently extracted by the high voltage accelerating pulse. The active anode plasma

diode designed and constructed for CHAMP is shown at left.

The active plasma anode diode has a number of important advantages. It can produce a

high purity beam of any gaseous ion. Since the ion production is separated from extraction

of the beam, greater control over beam characteristics is possible, and higher electrical

efficiencies can be achieved. Such a beam can be rep-rated, since far less ancillary gas

is produced (Quantum Manufacturing Techologies, Inc. routinely operates their ion beam,

which has this type of anode, at 10 Hz.)

The primary

research objective of this project is to design and construct a compact, rep-rateable IPIB

utilizing an active plasma anode diode. This device is known as the Continuous High Averge

power Microsecond Pulser (CHAMP), and when completed should produce a beam of 10-15 kA at

200-250 keV, in pulses of 1 us duration, repeated at 1-2 Hz. CHAMP utilizes a simple four

stage Blumlein (shown at left) to produce its 1 ms pulses,

resulting in a compact machine.

The primary

research objective of this project is to design and construct a compact, rep-rateable IPIB

utilizing an active plasma anode diode. This device is known as the Continuous High Averge

power Microsecond Pulser (CHAMP), and when completed should produce a beam of 10-15 kA at

200-250 keV, in pulses of 1 us duration, repeated at 1-2 Hz. CHAMP utilizes a simple four

stage Blumlein (shown at left) to produce its 1 ms pulses,

resulting in a compact machine.

Importance to LANL's Science and Technology Base and National R&D

Needs

Applications of IPIBs to treatment of materials are well documented in the published

literature, and include improved hardness and corrosion resistance through surface

microstructure refinement by rapid melt and resolidification, high rate production of

coatings by congruent condensation of material ablated by the ion beam, nanoparticle

production, and enhancement of surface catalytic action [12]. In this section, we will

review several other applications of particular interest to LANL's science and technology

base and the national R&D needs: 1) use as a portable, intense flash neutron source

for neutron resonance spectroscopy (NRS) of a dense plasma, neutron radiography, and

criticality measurements, and 2) use as an intense diagnostic neutral beam (IDNB) on an

advanced tokamak. Strong interest has been expressed within LANL for all of these

applications, and some funding has been obtained to pursue two of them (NRS and IDNB).

Neutron Resonance Spectroscopy

Dynamic NRS has been demonstrated at the LANSCE accelerator facility at LANL [13], but

a portable source is needed for making similar measurements on a variety of experiments

which cannot be moved to LANSCE, for example, the Atlas imploding liner facility scheduled

to be completed in late 2000. NRS is the only known method to make temperature

measurements in the several-eV range for strongly coupled plasma (SCP) experiments.

Experimental determination of SCP viscosity and equation-of-state has been identified by

LANL's Thermonuclear Applications Group as a critical component in improving our

understanding of secondary weapons physics. Once CHAMP is completed, LDRD funding has been

identified to characterize the intense deuteron beam, produce D-D neutrons (and hopefully

D-T neutrons in the future), and demonstrate the NRS technique. The goal is to have a

working high temperature diagnostic when Atlas comes on line in late-2000. A pulse of

>1012 14 MeV neutrons would be produced by hitting a tritiated metal target

with a 12 kA, 250 keV, 1 ms intense deuteron beam. These

neutrons, after moderation to epithermal energy, would irradiate a 4 cm3, 1-10

eV dense plasma containing a 1% solid density of indium or tantalum dopant. Neutrons are

resonantly absorbed, resulting in "holes" in the time-of-flight energy spectrum

detected some meters away. The temperature of the sample can be determined from the width

of the "holes". Calculations show that such an experiment fielded on Atlas would

could allow a few-percent accurate measurement of temperature in the 10 eV range.

More information on this application can be found here.

Neutron Radiography

The development of a high-resolution 14 MeV neutron radiography capability for

explosively driven experiments will provide an enhanced diagnostic capability for the

weapons community. Fast neutrons readily penetrate thick layers of heavy metals, while at

the same time being easily scattered by low-atomic-number materials, particularly hydrogen

bearing materials. This makes them an ideal tool for diagnosing shock phenomena in mixed

metal-explosive systems such as those of interest in nuclear weapons. Neutron radiography

is widely used as a non-evasive diagnostic for static systems, but has not been used

extensively for dynamic systems because of the lack of adequate neutron sources. Dynamic

applications require high-flux sources with millimeter-diameter-spot size for adequate

spatial resolution. An available neutron source employed in a recent Nevada shot generated

109 neutrons in a several square centimeter spot over multi-microsecond time

duration. A system adapted from CHAMP would be capable of several times 1012

neutrons in few-hundred-nanoseconds burst focused to a 4-mm-diameter spot. Spatial

resolution from this source would be less than 1 mm for a typical experiment. Work by LLNL

suggests that 1010 neutrons/cm2 on target is sufficient to resolve 1

mm3 voids in LiH sandwiched between depleted uranium plates, and larger

features can be resolved with neutron fluxes approximately 30x lower. By utilizing fast

capacitor banks which exist at LANL, coupled with well-understood pulse compression

techniques, the duration of the neutron pulse could be reduced to 10 ns. A team at KFK

(Karlsruhe, Germany) has generated a 50 kJ, 60 ns, beam of 1.4 MeV protons focused to a

4-mm-diam. spot [14]. For this application, we only need a 200 keV beam and factor of 5

less beam energy (about 10 kJ), so our beam requirements have been already been exceeded.

CHAMP can serve as a starting point and proof of principle, from which a faster pulse and

smaller spot size can be developed.

Criticality Measurements

Although underground testing has ended, our responsibility for maintaining the safety

and reliability of our weapons stockpile has not. Subcritical experiments have taken on a

high importance. A method of measuring instantaneous neutron multiplication (keff,

or equivalently, g) in an HE driven dynamic subcritical

assembly is needed to understand the effects of SNM alloying, aging, and fabrication

techniques on the performance of primaries. Determination of keff is one of the

primary methods of matching experimental weapons data to modeling results. In the past

(for instance, during the first nuclear test moratorium), similar measurements were made

using steady-state neutron sources. Such measurements are difficult to interpret because a

time-integrated value of keff is produced. In addition, cross talk with

neutrons derived from and scattered from surrounding non-SNM is difficult to eliminate. A

clean measurement is possible by looking directly at g's

produced by fission events derived from a very short (1-10 ns) neutron pulse. These g's are discriminated from the neutrons by time-of-flight. This is

effectively a measurement of the impulse response of the system. Such measurements are

possible with a modest extension of the state-of-the-art. Using an intense deuteron ion

beam impinging upon a tritiated target, it should be possible to produce 1010-1012

neutrons in a 10 ns pulse. Such a beam can be produced by a magnetized ion diode similar

to that developed for CHAMP, driven by a fast capacitor bank lower neutron fluxes (from

D-D reactions) over longer times have already been demonstrated with this technology on

the Anaconda IPIB at LANL. This technology is appropriate for downhole testing at NTS only

modest cost equipment (the diode and detectors) need be blown up.

Intense Diagnostic Neutral Beam for Advanced Tokamaks

Intense ion beam technology has been proposed to make a diagnostic neutral beam source

for active spectroscopic measurements on ITER [15]. Instead of the usual steady (or slowly

modulated) beams with less than 1 A/cm2 current density, microsecond pulses of

100 A/cm2 would be used. Operated at 100 keV/AMU, near the peak of the

charge-exchange recombination spectroscopy (CXRS) cross section, these beams would

increase signal-to-noise ratio because their high-intensity coupled with very short gating

times on the detectors reduce the bremsstrahlung background. Not only would these beams

provide vital measurements in the plasma core, but they would do so with time resolution

governed by the beam repetition rate. Such a single shot neutral beam was developed, and

it was demonstrated that effective charge neutralization could be achieved in a gas cell

at current densities of 20 A/cm2 (only a factor of 3-7 below the required value

depending on the diode diameter) [16]. The remaining essential issues in the application

of this technology to CXRS involve the development of a suitable high-power, repetitive

source that can be integrated into the ITER environment. CHAMP is an good prototype of

such a source.

For more photos of the CHAMP system, click here.

References

[1] V.M. Bystritskii and A.N. Didenko, High-Power Ion Beams, American Institute of

Physics, New York, 1989.

[2] K. Baumung, H.J. Bluhm, B. Goel, P. Hoppe, H.U. Karow, D. Rusch, V.E. Fortov, G.I.

Kanel, S.V. Razorenov, A.V. Utkin, and O.Yu. Vorobjev, "Shock-Wave Physics

Experiments with High-Power Proton Beams," Laser and Particle Beams, 14 181 (1996).

[3] M. Yatsuzuka, Y. Hashimoto, T. Yamasaki, and H. Uchida, "Amorphous Layer

Formation on Nickel-Alloy Surface by Intense Pulsed Ion-Beam Irradiation," Jpn. J.

Appl. Phys. 35 1857 (1996).

[4] A.J. Perry and J.N. Matossian, in C.R. Clayton, J.K. Hirvonen, and A.R. Srivatsa

(eds.), Advances in Coatings Technologies for Surface Engineering, The Minerals, Metals

& Materials Society, 1997, p. 3.

[5] D.J. Rej, H.A. Davis, J.C. Olson, G.E. Remnev, A.N. Zakoutaev, V.A. Ryzhkov, V.K.

Struts, I.F. Isakov, V.A. Shulov, N.A. Nochevnaya, and R.W. Stinnett, "Materials

Processing with Intense Pulsed Ion Beams," J. Vac. Sci. Tech. A 15 1089 (1997).

[6] B.P. Wood, I. Henins, W.A. Reass, D.J. Rej, H.A. Davis, W.J. Waganaar, R.E.

Muenchausen, G.P. Johnston, and H.K. Schmidt, "Large-Scale Implantation and

Deposition Research at Los Alamos National Laboratory," Nucl. Inst. Meth. Phys. Res.

B 96 429 (1995).

[7] G.E. Remnev, I.F. Isakov, M.S. Opekounov, G.I. Kotlyarevsky, V.L. Kuruzov, V.S.

Lopatin, V.M. Matvienko, M.Yu. Ovsyannikov, A.V. Potyopmkin, and V.A. Tarbokov,

"High-Power Ion Beam Sources for Industrial Application," Surf. Coat. Tech. 96

103 (1997).

[8] Rej, D.J., Davis, H.A., Olson, J.C., Remnev, G.E., Zakoutaev, A.N., Ryzhkov, V.A.,

Struts, V.K., Isakov, I.F., Shulov, V.A., Nochevnaya, N.A., Stinnett, R.W., Neau, E.L.,

Yatsui, K., and Jiang, W., "Materials Processing with Intense Pulsed Ion Beams,"

J. Vac. Sci. Technol. A, 15 1089 (1997).

[9] D.J. Rej, R.R. Bartsch, H.A. Davis, R.J. Faehl, J.B. Greenly, and W.J. Waganaar,

"Microsecond Pulse-Width, Intense, Light-Ion Beam Accelerator," Rev. Sci. Instr.

64 2753 (1993).

[10] Greenly, J.B., Ueda, M., Rondeau, G.D., and Hammer, D.A., "Magnetically

Insulated Ion Diode with a Gas-Breakdown Plasma Anode," J. Appl. Phys., 63 1872

(1988).

[11] Ueda, M., Greenly, J.B., Hammer, D.A., and Rondeau, G.D., "Intense Ion-Beam

from a Magnetically Insulated Diode with Magnetically Controlled Gas-Breakdown

Ion-Source," Laser and Particle Beams, 12 585 (1994).

[12] For a comprehensive review of material treatment with IPIBs, see Davis, H.A.,

Remnev, G.E., Stinnett, R.W., and Yatsui, K, "Intense Ion Beam Treatment of

Materials," Mater. Res. Soc. Bull., 21 58 (1996).

[13] Funk, D.J., Asay, B.W., Bennett, B.I., Bowman, J.D., Boat, R.M., Dickson, P.M.,

Henson, B.F., Hull, L.M., Idar, D.J., Laabs, G.W., London, R.K., Mace, J.L., Morgan, G.L.,

Murk, D.M., Rabie, R.L., Ragan, C.E., Stacy, E.L., and Yuan, V.W., "Dynamic

Measurement of Temperature Using Neutron Resonance Spectroscopy (NRS)," Shock

Compression of Condensed Matter, Amherst MA, July 27 - August 1, 1997, AIP Conf. Proc. 429

887 (1998).

[14] Bluhm, H.J., Hoppe, P.J.W., Laqua, H.P., and Rusch, D., "Production and

Investigation of TW Proton-Bemas from an Annular Diode Using Strong Radial Magnetic

Insulation Fields and a Preformed Anode Plasma Source," Proc. IEEE, 80 995 (1992).

[15] Rej, D.J., Henins, I., Fonck, R.J., and Kim, Y.J., "Intense Diagnostic

Neutral Beam Development for ITER," Rev. Sci. Instrum., 63 4934 (1992).

[16] Bartsch, R.R., Davis, H.A., Henins, I., and Greenly, J.B., "High-Intensity

Neutral Beam for Beam-Spectroscopy Diagnostics," Rev. Sci. Instrum., 66 306 (1995).

Return to Applied Plasma Technologies homepage

Return to P-24 homepage

For approximately

eight years, LANL has operated the Anaconda IPIB [9]. Anaconda utilizes the ballistically

focused, magnetically insulated ion diode shown at left, a common anode design. Ions are

formed by the flashover of a conical annulus of Lucite attached to the anode electrode.

Ions are accelerated across a 300 kV gap toward nested, truncated metal cones that form

the cathode. Field-emitted cathode electrons are prevented from shorting the anode-cathode

gap by a transverse magnetic field generated by pulsed electromagnets ("slow

coils") which surround the cathode cone. The azimuthal E(B drift of electrons in the

anode-cathode gap causes them to stay confined. The diode is directly connected to a Marx

generator operated to produce a 300 keV, 30 kA, 400 ns beam. The ballistic focus of the

diode produces a minimum spot size of about 100 cm2, yielding energy fluences

at focus of about 30 J/cm2.

For approximately

eight years, LANL has operated the Anaconda IPIB [9]. Anaconda utilizes the ballistically

focused, magnetically insulated ion diode shown at left, a common anode design. Ions are

formed by the flashover of a conical annulus of Lucite attached to the anode electrode.

Ions are accelerated across a 300 kV gap toward nested, truncated metal cones that form

the cathode. Field-emitted cathode electrons are prevented from shorting the anode-cathode

gap by a transverse magnetic field generated by pulsed electromagnets ("slow

coils") which surround the cathode cone. The azimuthal E(B drift of electrons in the

anode-cathode gap causes them to stay confined. The diode is directly connected to a Marx

generator operated to produce a 300 keV, 30 kA, 400 ns beam. The ballistic focus of the

diode produces a minimum spot size of about 100 cm2, yielding energy fluences

at focus of about 30 J/cm2.  There are several

limitations of this solid flashover ion diode design. The beam produced consists of

carbon, hydrogen, and oxygen ions, with little composition control possible. Anode debris

(molten bits of anode material) is produced, which impacts and contaminates the object

being treated. Such debris is shown at left. Finally, due to the large amount of vapor and

anode debris produced, it requires a significant amount of time (seconds to minutes) to

pump the vacuum chamber down in preparation for the next shot.

There are several

limitations of this solid flashover ion diode design. The beam produced consists of

carbon, hydrogen, and oxygen ions, with little composition control possible. Anode debris

(molten bits of anode material) is produced, which impacts and contaminates the object

being treated. Such debris is shown at left. Finally, due to the large amount of vapor and

anode debris produced, it requires a significant amount of time (seconds to minutes) to

pump the vacuum chamber down in preparation for the next shot. A better anode design is the active anode plasma diode developed

by John Greenly at Cornell University.[10, 11]. This diode looks very much like the

Anaconda diode shown above, but replaces the solid flashover anode with a plasma produced

by breaking down gas which has been puffed across the face of the anode from a fast valve

on the diode axis. The anode face consists of a "fast" inductive coil potted in

epoxy. Pulsing the fast coil breaks down the gas into a plasma. This plasma is stagnated

against the transverse magnetic field produced by the slow coils, and ions are

subsequently extracted by the high voltage accelerating pulse. The active anode plasma

diode designed and constructed for CHAMP is shown at left.

A better anode design is the active anode plasma diode developed

by John Greenly at Cornell University.[10, 11]. This diode looks very much like the

Anaconda diode shown above, but replaces the solid flashover anode with a plasma produced

by breaking down gas which has been puffed across the face of the anode from a fast valve

on the diode axis. The anode face consists of a "fast" inductive coil potted in

epoxy. Pulsing the fast coil breaks down the gas into a plasma. This plasma is stagnated

against the transverse magnetic field produced by the slow coils, and ions are

subsequently extracted by the high voltage accelerating pulse. The active anode plasma

diode designed and constructed for CHAMP is shown at left.  The primary

research objective of this project is to design and construct a compact, rep-rateable IPIB

utilizing an active plasma anode diode. This device is known as the Continuous High Averge

power Microsecond Pulser (CHAMP), and when completed should produce a beam of 10-15 kA at

200-250 keV, in pulses of 1 us duration, repeated at 1-2 Hz. CHAMP utilizes a simple four

stage Blumlein (shown at left) to produce its 1 ms pulses,

resulting in a compact machine.

The primary

research objective of this project is to design and construct a compact, rep-rateable IPIB

utilizing an active plasma anode diode. This device is known as the Continuous High Averge

power Microsecond Pulser (CHAMP), and when completed should produce a beam of 10-15 kA at

200-250 keV, in pulses of 1 us duration, repeated at 1-2 Hz. CHAMP utilizes a simple four

stage Blumlein (shown at left) to produce its 1 ms pulses,

resulting in a compact machine.